> Blast Solutions / Blast Rooms / Blast Room Roller Doors

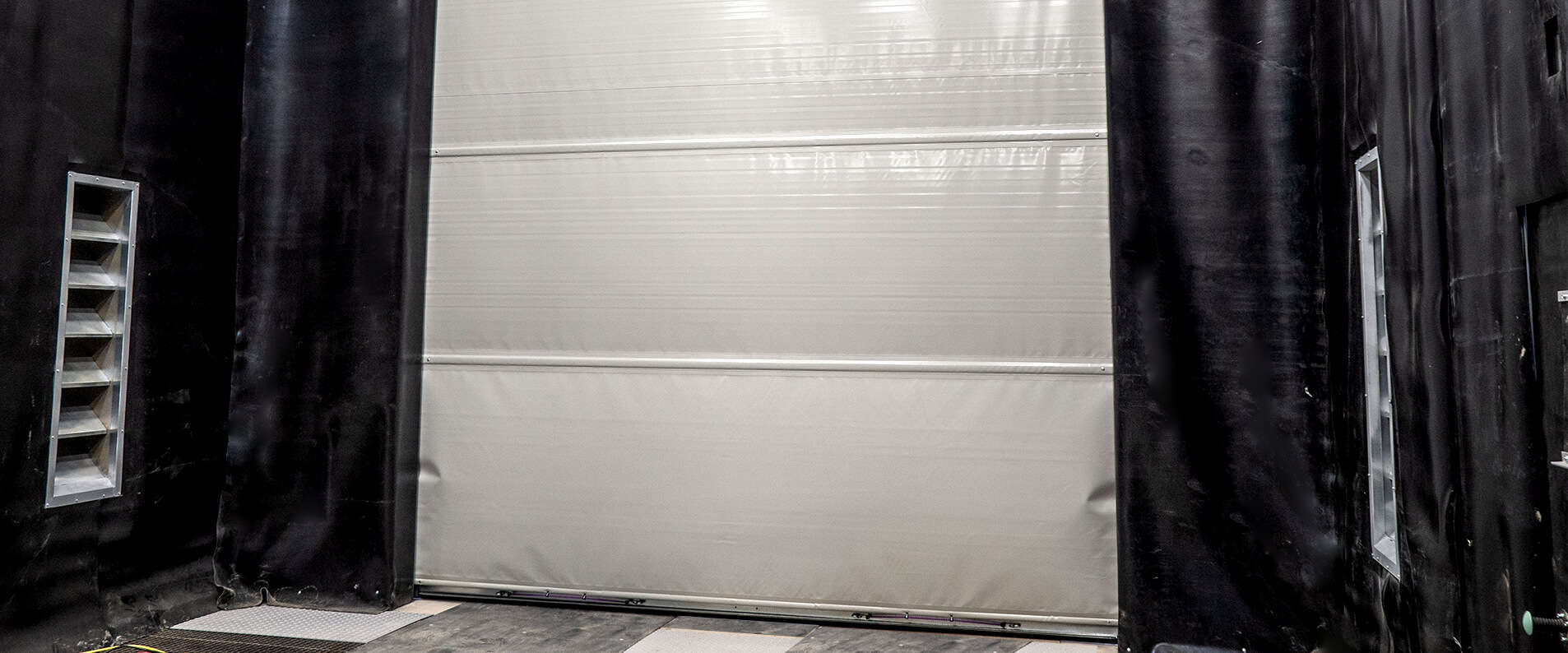

Blast Room Roller Doors

Getting the most from factory space or real estate is a challenge for manufacturing managers worldwide. How do we maximise our available space when expansion or relocation are not options?

Blast and spray functions are space-hungry processes with heavy-duty construction demands, and, up until now, blast booths or blast rooms required heavy hinged doors to withstand the impact of abrasive.

While hard-wearing, these doors are slow to fit and, as they swing open, need a considerable amount of dedicated real estate space to be kept clear. On a large booth, that additional space used by hinged doors can be considerable - up to 12.5m² for 5m wide doors.

Roller Doors

What if hinged doors were obsolete? What more could you do with the extra space? At Airblast Limited, we have developed a unique lined roller door that completely eradicates the need for hinged doors and helps facilities to recover unproductive factory space or real estate.

Historically, roller doors were thought to be unsuitable for blast booths due to abrasive grit damaging the mechanisms. But our new space-saving blast shutters are lined with an innovative fabric to absorb abrasive impact and protect moving parts. These protective elements drop down with the roller element providing a secondary door to protect the mechanisms.

“We can only deliver the quality we are known for if we focus on highly efficient manufacturing processes. Airblast understood this and developed a really innovative solution.”

– NTM GB

Constructed from high quality galvanised steel, our lined roller doors are proven to be highly robust, quick to fit, and completely resilient to media ingress. The weight advantages of our new doors mean they can be deployed on very large booths with ease, a huge benefit for large vehicle production and maintenance facilities.

They are electrically operated, are completely secure when closed, and 100% weather proof, making them ideal for outdoor sites.

Available in widths up to 5m, our roller door blast booths are generating interest from maintenance managers and vehicle manufacturers around the UK. NTM-GB produces RCVs at their Midlands facility and recently commissioned a new booth. They said: “The roller door is a relatively small component delivering large benefit.

The space-saving roller door is just one of the many innovations with which Airblast is advancing the field of surface preparation. Space management, noise reduction, dust extraction, and humidity control are just some of the advantages of our groundbreaking solutions.

Modular Blast Rooms

Modular systems from Airblast Limited offer a flexible and customisable approach to blast room creation.

Sound Attenuated Blast Booths

Blast room design from the leaders in blast and spray innovation. Sound attenuated blast booths improve safety and reduce noise.

Bespoke Blast Rooms

Airblast Limited designs, manufactures and installs Blast Rooms for a variety of market sectors from Aerospace, Oil & Gas, and Marine to Road Haulage, Rail, and Wind Power.

Containerised Blast Rooms

Airblast Limited offers a range of containerised blast room systems. These are an affordable solution when a weatherproofed or transportable blast room is required.

Weatherproof Blast Rooms

Weatherproof blast rooms utilise the structural steel of a portal frame building to replace the blue 'diaphragm' plates featured on modular blast rooms.

Plastic Media Blast Rooms

Airblast Limited is the UK's premium manufacturer of Plastic Media Blast Rooms for various PMS applications across a range of industry sectors

Kit Form Blast Booths

Our new KFB blast booth offers a great value alternative to modular, sound attenuated and bespoke booths. They can also be self-assembled or erected by our experienced engineers.

Wind Turbine Production Facilities

Airblast Limited has extensive experience in the design and installation of blasting facilities that meet the specific demands of wind turbine tower manufacturers.

Marine Production Facilities

Specialists in surface finishing and preparation facilities, Airblast has been providing turnkey blast and paint solutions for international marine customers for five decades.